Parts Tracking and Maintenance | Barcode Scanning in the Airline Industry

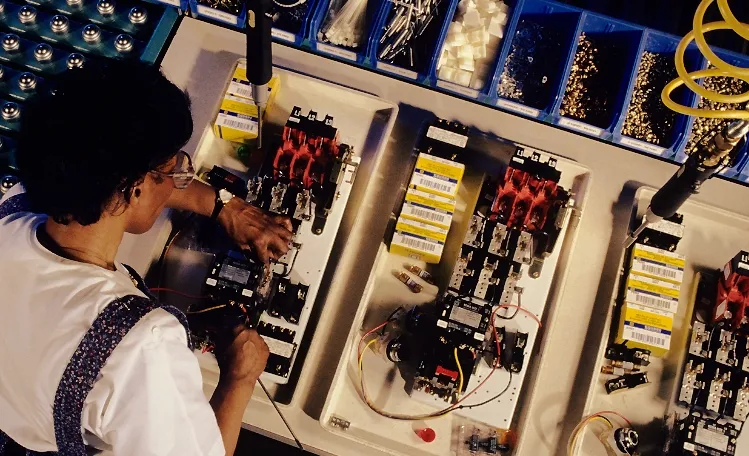

Aircraft maintenance involves a complex process of regular inspections and parts replacements. Effective parts tracking is crucial to ensure that all components are in good condition and functioning properly. Thanks to digital and mobile solutions, airlines can now streamline the parts tracking process using barcode scanning. With a robust mobile app, maintenance operators can quickly track and find different parts, from the aircraft to the warehouse or even while in service. In this blog, we will discuss the benefits of barcode scanning in parts tracking and how Dynamsoft Barcode Reader SDK can help.

See it in action: barcode scanner →

The Challenges of Barcode Scanning for Direct Part Marking (DPM) Codes

While barcode scanning has revolutionized the parts tracking process, not all barcode readers are created equal. Barcode scanning for Direct Part Marking (DPM) codes poses specific challenges, including:

- Poorly printed or incomplete DPM codes that most barcode scanners fail to scan.

- DPM codes that are etched directly onto parts, resulting in low contrast, making it difficult for ordinary barcode readers.

- Materials like glass and metal that cause glare or reflection, making DPM code scanning even more challenging.

- Parts and surfaces that are uneven, curved, or irregular, which most barcode scanners struggle to read.

Low-Quality Camera

Low-quality cameras make barcode reading difficult for Direct Part Marking (DPM) codes due to poorly written or incomplete codes, low-contrast markings, and glare and reflection. High-quality cameras are needed to overcome these hurdles, especially on uneven terrain that limits barcode scanning.

The Solution: Dynamsoft Barcode Reader SDK

To overcome these challenges, Dynamsoft Barcode Reader SDK offers a powerful solution for airlines. The SDK supports decoding Direct Part Marking (DPM) Data Matrix codes, making it ideal for anyone who manages or tracks components, devices, or equipment with permanently etched DPM barcodes. It can effectively read a DPM barcode, whether it is etched into silicon, metal, plastic, or glass. Additionally, it works perfectly fine with incomplete, curved, angled, and low contrast barcodes, making it the perfect solution for DPM code scanning.

Benefits of Using Dynamsoft Barcode Reader SDK

Implementing Dynamsoft Barcode Reader SDK offers the following benefits to airline companies:

- Improved accuracy and cost savings through correct information provided to the right person for labor and process accuracy.

- Streamlined operations and improved efficiencies through mobile barcode scanning apps that can track and find aircraft parts anywhere in the airport or warehouse.

- Enhanced reliability and safety by ensuring all parts are in good condition and functioning properly.

Contact Us to Try Dynamsoft Barcode Reader SDK for Free

If you’re interested in seeing how Dynamsoft Barcode Reader SDK can streamline operations for your airline company, contact us today for a free trial or demo. You can also send us an email at sales@dynamsoft.com. With our powerful barcode scanning solution, you can take your parts tracking process to the next level and improve your overall operational efficiency.

Blog

Blog