Data Matrix Integration for better Accuracy in Printed Circuit Board Identification

In the complicated world of Printed Circuit Boards (PCBs), exact circuit board component identification is essential for easing out troubleshooting. It ensures that the electronic devices function efficiently.

This article will explore the role of Data Matrix codes for enhanced efficiency in PCB parts identification. Data Matrix codes play an important role in simplifying identification processes by offering an easy solution to encode and decode information related to PCB components.

Let us delve into the role of Data Matrix codes in Printed Circuit Board identification.

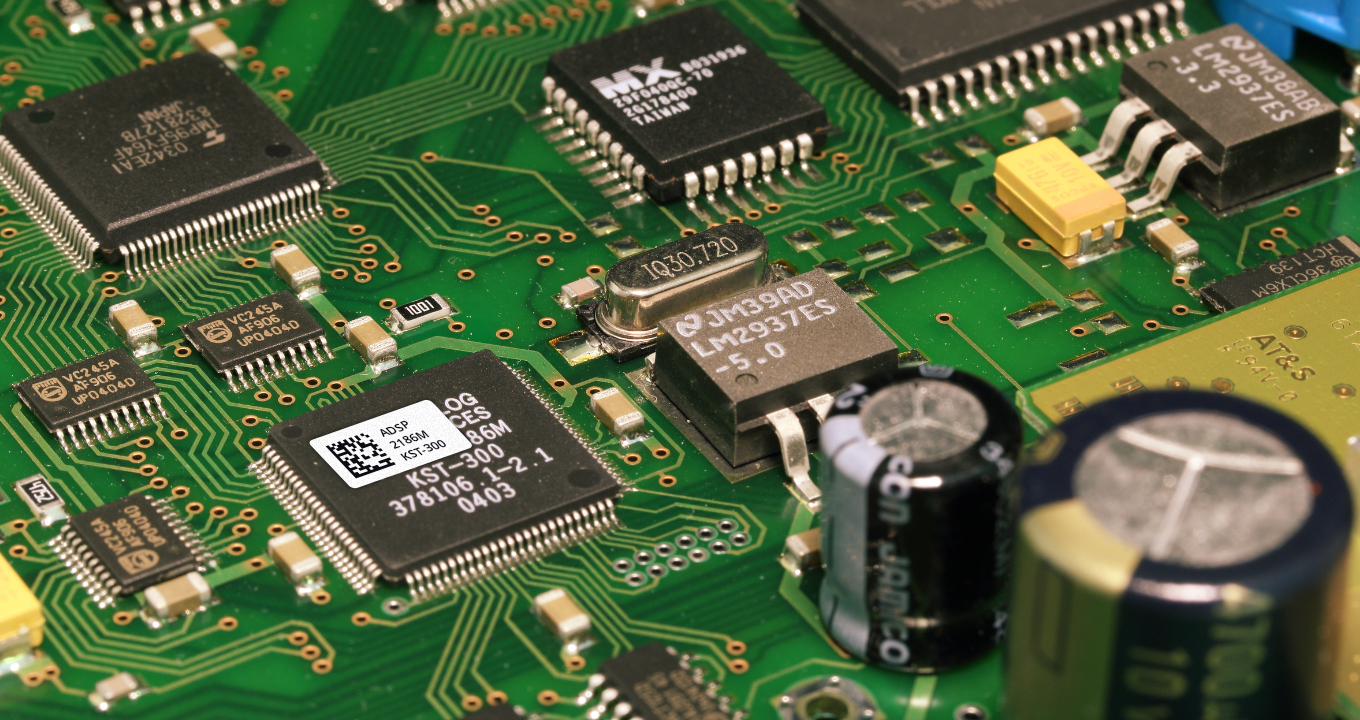

PCB Components Identification

In PCBs, accurate identification of components is crucial for flawless working of the circuit board and error correction. It impacts the performance and lifespan of electronic devices.

Any anomaly in component identification can lead to performance issues, circuit malfunctions, or even complete circuit breakdowns. The exact identification of PCB components poses many challenges. Let’s have a look at them in detail:

Challenges of PCB Component Identification

Identification of PCB components is a challenging task due to the variations of sizes, shapes, and labeling conventions.

-

Minuscule Dimensions: PCB parts are minuscule in size. Visually identifying such small parts that look almost identical is a huge challenge that can lead to identification errors.

-

Component Diversity: The variety in the shapes and sizes of PCB parts adds to the identification difficulty. With PCBs adorning multiple components, each having different shapes and sizes, and having different specifications can make it challenging to bifurcate and identify them.

-

Surface Mount technology: Usage of surface-mount technology has added to the difficulty of identification of PCB components. The soldering joints and higher packaging density of small parts make PCB parts identification difficult.

-

Poor Camera Quality: Suboptimal camera performance adversely impacts the efficacy of Data Matrix code scanning for PCB components. Poor camera quality leads to distorted image capture of the barcodes, necessitating an extended decoding process. Eventually, it increases the likelihood of error messages or inaccurately decoded information.

Furthermore, subpar cameras typically lack autofocus functionality, instead employing a fixed focus set at infinity, adding to the challenge in PCB component identification. The resultant blurred images generated by fixed-focus cameras set to infinity focus present a significant obstacle in accurately identifying PCB components.

These challenges require a solution that can effectively deal with these issues. DataMatrix codes have effectively presented themselves as a savior to mitigate these challenges.

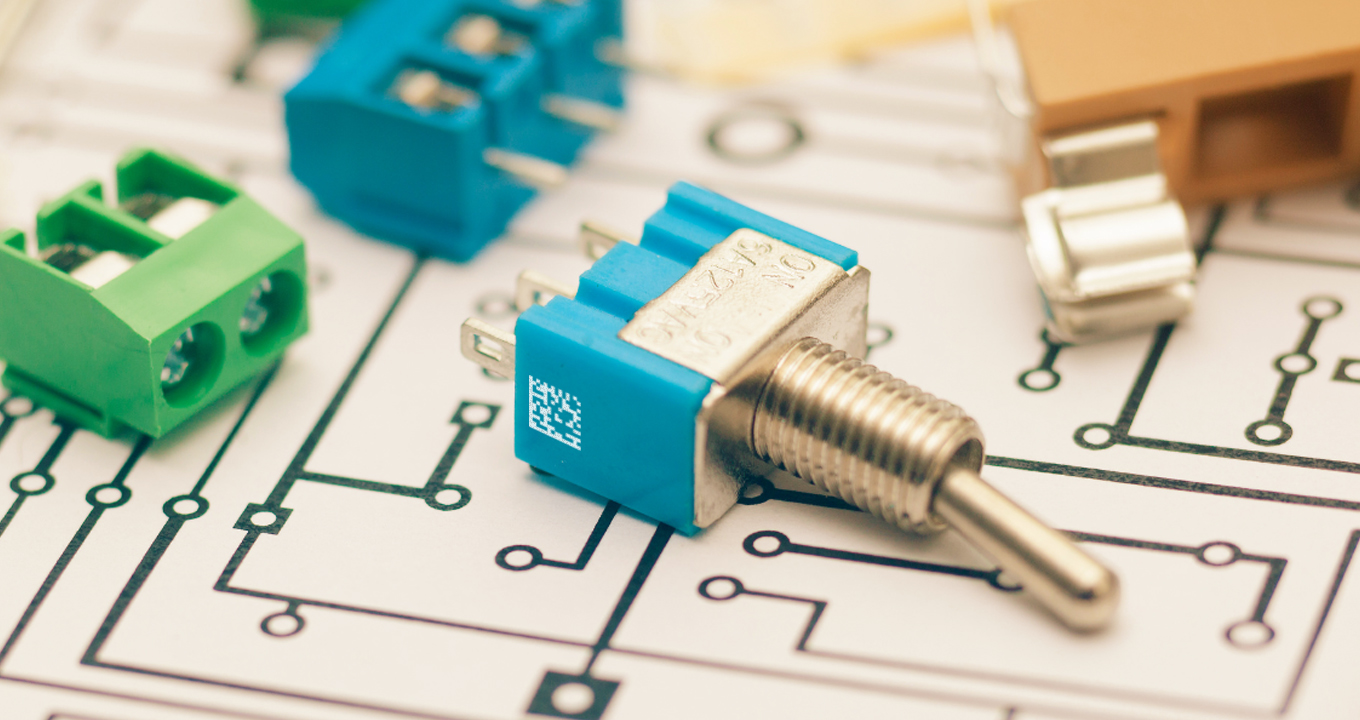

Understanding DataMatrix Codes

DataMatrix codes are a 2D barcode type that can store large amounts of data in restricted space. Integrating them can significantly increase the reliability of the identification of PCB components. Their ability to store large data in a small space makes them an ideal choice for PCB parts identification, especially for components that are small in size and have long technical specifications.

To ensure accurate circuit board component identification, PCBs are marked with solder-resistant, machine-readable, and permanent DataMatrix codes using laser markings. This section provides an all-inclusive analysis of the different laser marking techniques employed for printing DataMatrix codes on PCBs.

Laser Marking

Laser markings offer permanent and precise DataMatrix marking for accurate readability. To enhance the quality of DataMatrix printing, three wavelength ranges are offered for various PCBs: 355nm (UV), 1,060-1,070nm (infrared), 10,600nm (infrared).

To make the DataMatrix printing customized, you have the choice to pick your preferred laser marking type from:

Basic Laser Marking

This solid-state system offers premium quality laser markings of DataMatrix codes on PCB. They are quick and the machines can be integrated into the production facility. The most common laser markers are:

- Fiber laser markers

- UV laser markers

- CO2 laser markers

Advantages

- Highly accurate even on minute parts.

- Ideal for a variety of PCB components made from different materials.

- Solder resistant.

Laser Marking: Engraving

Engraving using laser marking removes the material from the surface of the PCB to be marked with DataMatrix. The laser beam is penetrative on the surface of the PCB to remove the material. Because of the heating and reaction with air, the color of the engraved area changes. This further helps the DataMatrix code stand because of laser marking. The common laser marker used for engraving is Fiber Laser Marker.

Advantages

- Accurate, precise and fast marking system.

- Offers permanent and durable marking solutions.

- Appropriate for different PCB components made from plastics, metals, and ceramics.

Laser Marking: Color Change/Frothing:

In the case of plastic PCBs, color change or frothing is the most common system for laser marking. In these cases, plastic absorbs laser light and the carbon and color pigments in the plastic get destroyed and evaporate because of the heating. This results in color change and frothing of the plastic. The commonly used laser markers for this system are:

- Fiber laser marker

- UV laser marker

Advantages

- Accurate, precise and fast marking system.

- Solder-resistant marking.

- Permanent and durable marking solutions.

- Appropriate for different PCB components made from plastics, metals, and ceramics.

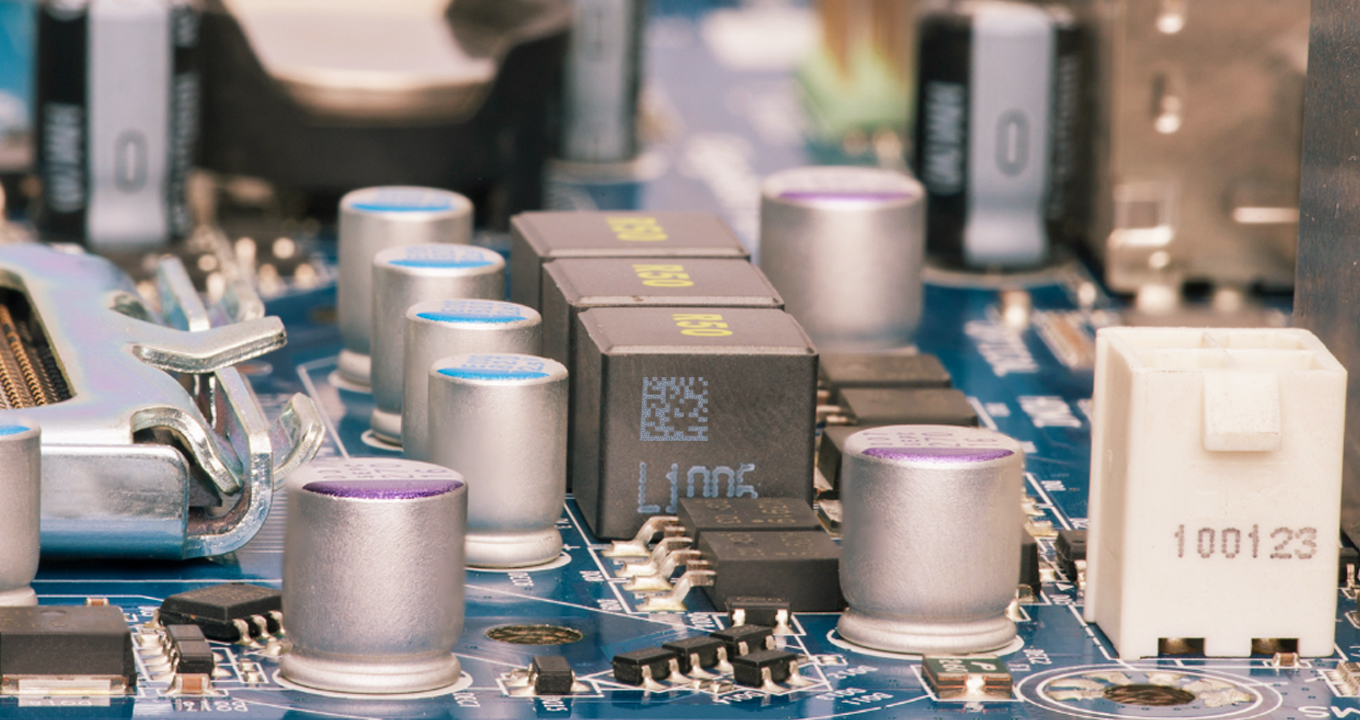

Uses of DataMatrix codes in PCB Component Identification

Some of the undeniable uses of the DataMatrix in PCB component identification are:

-

PCB parts identification: DataMatrix codes on the PCB components are encoded with the information necessary for their thorough identification. All the details regarding the PCB components can be decoded by using a barcode scanner. This decoded information becomes a key source to identify the components and their specifications.

-

Reduced data entry errors: While entering the details of the PCBs into the inventory system, there are chances of typing errors. This can completely alter its specifications. Circuit board scanners have the added advantage of reducing manual data entry errors as all the details are extracted and entered automatically from the decoded data.

-

Faster Identification process: The identification process becomes fast, as by a single scan of PCB marking codes, all the details about the components are available within a few seconds.

Integration of DataMatrix Codes for PCB identification

To ensure an optimized identification process, it is very important to understand the integration details and implement best practices.

Best Practices for DataMatrix Integration

Some of the best practices to follow while integrating DataMatrix codes in your PCB systems are:

-

Validate Code Dimensions for Precision: The PCB and its components are generally very small in size. Hence, it becomes very important to consider the size of the DataMatrix code. The DataMatrix code should perfectly fit into the available space such that no part of the code goes missing.

-

Optimize DataMatrix Placement: All the components in a PCB are tightly packed in the available space. The PCB barcode should be ideally printed at a location where they are easily accessible for scanning and do not interfere with other components. The PCB component code should also not interfere with the circuit causing an interference in the working of the component.

-

Utilize Advanced Printing Technology: Ensure to use good printing technology that offers the best print quality in the available area. Highly advanced DataMatrix code printing machines are available that offer clear prints. They also ensure that the code is clear, and no broken lines are printed.

Besides addressing the technical intricacies of DataMatrix integration, ensure compliance with industry standards.

Dynamsoft Barcode Reader SDK for Scanning PCB Barcodes

The integration of DataMatrix technology is a foolproof method to identify Printed Circuit Board components. It efficiently deals with the size constraint issue of the PCB components and ensures accurate and error-free identification. As PCBs are evolving and becoming smaller in size and widening their functionality, a DataMatrix can be a trusted way to enhance efficiency in Printed Circuit Board Identification.

At Dynamsoft, we believe in evolving our products along with the evolution of the PCBs and offering robust PCB barcode scanner SDKs. Leverage our SDK to get the best performance for decoding PCB component codes. Get in touch with our technical team to understand how our SDK will help your use case.

Blog

Blog