Importance of Industrial Cameras in Barcode Scanning

Why Industrial Cameras are Important for Barcode Scanning?

Industrial cameras are needed for barcode scanning because they are designed to provide high-quality, reliable image capture in industrial environments. They are built to withstand harsh conditions such as extreme temperatures, humidity, and vibration, which are common in manufacturing and logistics facilities. Industrial cameras also offer features such as high-speed image capture, advanced image processing, and built-in lighting that are essential for accurate barcode scanning in challenging conditions. These cameras are an important tool for businesses that need to automate their inventory management, improve production efficiency, and ensure product traceability.

In this blog we explore how robust barcode scanning solutions can be paired with industrial cameras in a wide range of industries to increase accuracy and consistency in the most demanding conditions.

Role of Industrial Cameras in Barcode Scanning

You can’t expect an average camera to capture the tiniest of Direct Part Marking (DPM) codes engraved on printed circuit boards (PCBs) or complex medical components. For these purposes, you’ll need a specialized camera with high resolution, optical zoom, and advanced autofocus to consistently capture tiny barcodes.

Similarly, a high frame rate and image stabilization camera will help you capture objects on a conveyor belt. Some cameras even have temperature stability to operate within a wide temperature range for optimal performance in the most challenging industrial environments.

Applications of Industrial Camera for Robust Barcode Scanning

An industrial camera can be employed in diverse ways according to the materials being scanned and the specific environmental challenges of each industry. We have listed some important uses of industrial cameras to achieve robust barcode scanning.

Raw Material Identification for Rubber Mixture

When the features of an industrial camera meet the advanced barcode decoding algorithms of a robust barcode scanner, the barcodes on the ingredients of a rubber mixture can be easily decoded to identify raw materials accurately. Hence, errors are minimized in the blending process, which further helps enhance the quality of the final product.

Slabs and Coils Assignment Verification

Robust enterprise-grade barcode scanning solutions are needed to read challenging barcodes such as dense, tiny, or blurred- all of which are common on coils and slabs. Employing a powerful barcode scanning solution with industrial cameras helps ensure the accurate placement of slabs and coils during manufacturing. Doing so also maintains order and prevents errors that could affect the quality of final products.

Order Fulfillment for Accuracy and Reduced Shipping Errors

Industrial cameras act as a support system for barcode scanners in order fulfillment. While a state-of-the-art barcode scanner supports all shipping barcode types, an optimal camera ensures accuracy and reduces errors by clearly capturing the minutest details. Hence, they help guarantee that the right products are delivered to the right locations, lowering the chances of errors.

Baggage Barcode Scanning on Conveyor Belt

At airports and logistics hubs, barcode scanners capture barcodes on baggage moving on conveyor belts. While advanced barcode scanners are built to read barcodes in motion, using a high-quality camera with critical features, such as high frame rate, low latency, and high resolution, further helps enhance the efficiency of baggage handling systems by allowing for rapid automated sorting.

Carrier Position Tracking on Automated Material Handling System (AMHS)

Industrial cameras help monitor carriers moving around on automated material handling systems in factories. Leveraging the capabilities of a robust barcode scanner improves the efficiency of the process by scanning multiple barcodes from long distances during carrier position tracking on AMHS.

Accurate Sample Tracking Through Various Stages of Production

Industrial cameras capture all stages of product creation- installed at different production facility locations. An advanced barcode scanning solution supports reading barcodes at skewed and wide angles without issues. Some enterprise-grade barcode readers can even perform well with low-resolution cameras, decoding barcodes at multiple stages for accurate sample tracking through various stages of production, from raw materials to finished goods.

Identification of PDF417 Barcodes on Raw Products in Packaging

PDF417 barcodes are widely used on raw products in packaging to ensure accurate identification and tracking. Advanced barcode scanners quickly scan these barcodes on raw materials. Employing a specialized industrial camera further enhances the process to confirm that the right materials are used for each product. It adds an extra layer of accuracy to quality checks and maintains consistency.

Battery Cell Quality Assurance

Tiny barcodes on battery cells are very challenging for many barcode scanners. These require a barcode scanning solution with reliable and robust barcode detection algorithms. Industrial cameras further support barcode scanners for battery production by accurately focusing the tiny barcodes on each battery cell to assist with quality assurance measures.

Identification of Data Matrix Codes on PCBs and Electronic Components

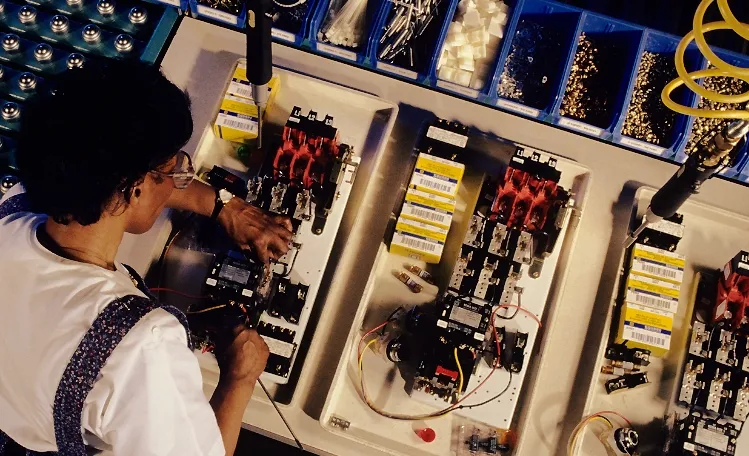

Identifying the DataMatrix codes on PCB components is challenging as they vary in shape and labeling conventions. Only an enterprise-grade barcode scanner can handle such codes. Furthermore, using a suboptimal camera will make the scanning process less effective. The ideal solution is to leverage an optimal industrial camera and an advanced barcode scanning solution to scan DataMatrix codes on PCB components and electronic components, even in challenging conditions, such as tiny codes, inconsistent lighting conditions, varied surface textures, etc.

Verification of Product Details on the Assembly Line

A high-speed barcode scanner can help verify product details by scanning barcodes on products running on assembly lines for accurate quality checks before the item reaches the next production stage. Accuracy is another factor that decides the barcode scanning performance on assembly lines. When paired with an optimal camera, barcode scanners can easily capture and analyze critical features, such as markings and dimensions, enabling real-time quality checks. As a result, errors are reduced, product consistency is maintained, and overall efficiency is improved.

What to Consider When Selecting an Industrial Camera for Barcode Scanning

Looking for a camera for barcode scanning for your use case? We have created a guide that covers all the aspects, features, and analysis of usage scenarios to consider when buying an industrial camera for barcode scanning.

If you still have questions, contact our technical support team for a detailed discussion.

Conclusion

Dynamsoft Barcode Reader SDK (DBR) is designed for fast, accurate barcode scanning in the most challenging conditions. It is a highly customizable barcode scanning solution, to leverage the maximum benefits for accurate capture with your industrial camera. DBR works well with different types of cameras, including industrial, programmable digital, webcams (document cameras), and even smartphones. The barcode scanning SDK, when used with Dynamsoft Camera Enhancer, is designed to maximize capture using even with low-resolution cameras.

Check out this demo to see it in action.

Blog

Blog