Guidelines for Generating and Printing Barcodes

Whether you are working with an inventory system, a medication administration system, or another system that uses barcodes, chances are you may on occasion encounter unreadable barcodes. Software developers certainly have levels of control over the accuracy of barcode recognition in an application. But, for end users of a barcode application, it would seem there aren’t many options to improve barcode recognition. In actuality, end users do have a few options for improving barcode reading precision. Let’s look at some of the most common areas you can influence.

Image Resolution

How effectively a barcode is recognized largely depends on the quality of the barcode image during barcode generation. In fact, it can easily be argued that image resolution is the most important factor in barcode recognition accuracy. We previously addressed resolution concerns in the post “Improve the Barcode Recognition Rate of Your Application,” which was for software developers. But, this factor is important to end users too. Thus, it warrants mentioning it again.

Generally, a barcode reader processes the counting of pixels in an area to determine the width and location of a particular bar. So, anything that can interfere with this process can impact barcode recognition accuracy. Usually, a minimum of 200 dpi is needed for acceptable barcode recognition. DPI stands for “dots per inch.” Basically, the more dots per inch that make up an image, the more resolution it has. So, the higher you can go in resolution the better.

Bear in mind that the lower the resolution the more likely the symbol will lack the pixel density needed for good recognition. So if you have a choice, always go for a higher dpi. Generally, for 1D barcodes, it’s understood at least three pixels are needed per smallest bar and gap in a symbol. For 2D barcodes, it’s usually around five pixels. Sometimes, despite proper resolution settings, good pixel density just isn’t there. This could be for many reasons – poor quality labels or printer, and so on. So, check all your device settings to ensure they are delivering the necessary DPI.

Location

The location of the barcode involves where it is physically located on a page, box or other item. It’s important to consider user scenarios for the item. This is to ensure its placement isn’t going to be where it’s likely to be damaged. For example, if you’re placing it on a printed health record, you probably want to avoid putting the barcode where users commonly staple another item with the barcoded item.

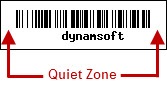

Quiet Zone

In a typical scenario, software can be used to scan the entire width and height of a page, box, etc. in order to find a barcode. Part of having success in such a scan is having a properly defined quiet zone. A quiet zone is a blank area or margin on either end of a bar code. That blank area tells a barcode scanner where the barcode starts and stops. Remember that quiet zone specifications vary depending on the barcode symbol being used. Usually, at least an eighth of an inch is a minimal requirement.

A barcode reader relies on this “quiet zone” to pick up the relevant area only for barcode decoding. So remember to keep this quiet zone clean.

Type of Materials

Other barcode recognition problems can arise from the type of materials that may surround or cover the barcode. For example, if tape is placed over a barcode that isn’t opaque enough, barcode recognition can of course be negatively impacted. The lack of a reflection from objects that aren’t opaque enough will hurt barcode recognition. Just as much as non-reflective materials can impact barcode recognition, materials that are too reflective can too. While a non-opaque object can reduce reflection, highly reflective materials can distort them. If a barcode is to be printed directly on a box, make sure the box material isn’t going to cause problems. For example, package or box designs can have contrasting colors. Thus, they can act as introduced artifacts that impact barcode recognition.

Printer

If your printer’s quality is not up to snuff, it can also introduce artifacts. Anyone with enough experience using inkjet printers has come across foreign dot patterns or lines introduced on a printed image. Resolving such issues could be as simple as cleaning your print head or it may demand investing in new printing hardware.

Contrast

This brings up a related point about contrast. Symbol contrast is a must. Black and white is best. This contrast is just as true at an edge of a barcode. For example, let’s say you print a barcode on a white label with an inadequate quiet zone and then place that label on a dark-colored box. The edge of white label against a black box could be inaccurately recognized as the start of another bar in a bar code symbol. So, be careful of how you print your labels and what you’re putting them on so proper symbol and edge contrast are realized.

Avoiding Other Defects

Physical defects in a barcode can include empty areas that shouldn’t be empty or artifacts in areas that should be empty. This doesn’t just mean missing ink or ink in wrong places. It can include foreign matter, such as pen marks, grease, glue, dirt and the like. Extra ink or a lack of ink, along with foreign substances, can fool a barcode scanner into thinking there is a bar there that really isn’t there or that there is not a bar there when there really is one. Thus, you should start with physically checking your printed bar codes to ensure high quality, artifact-free symbols will be implemented. Also, a mismatch in the printed resolution of barcode symbols and software settings can lead to poor barcode recognition. So, verify the printed resolution of your barcodes so the scanner’s settings can be made to match.

Summarizing

Improving barcode recognition doesn’t just involve software developers or hardware manufacturers. As a barcode application user, you have power to also positively influence barcode technology performance. Overall, barcode reading depends on how you generate the barcode (its resolution) and where you place it. Although sophisticated barcode reader software can help, it is still crucial for you to follow best practices detailed herein. End users working together with their software and hardware providers will maximize results.

Blog

Blog