How Batch Barcode Scanning Improves Warehouse Accuracy and Efficiency

Solving the barcode bottleneck through high-speed, batch scanning

As supply chains grow more complex and time-sensitive, warehouses are expected to move faster, handle more SKUs, and maintain near-perfect accuracy—all without increasing headcount. While automation has transformed many warehouse operations, one critical task still slows everything down: manual barcode scanning. For many teams, the process of scanning items one by one remains a bottleneck within otherwise streamlined workflows. As volumes grow and demands tighten, operations leaders are rethinking barcode scanning—and exploring new methods to scale accuracy and speed simultaneously.

The Barcode Bottleneck

Barcodes power almost every warehouse process—from receiving to shelving, order picking, packing, and auditing. But despite widespread automation elsewhere, barcode scanning itself has frequently remained a manual, one-by-one task.

This creates a growing problem as operations scale:

- Workers spend valuable time scanning hundreds (or thousands) of items individually

- Errors from missed or duplicated scans introduce downstream issues

- Bottlenecks form at key checkpoints such as receiving or inventory audits

- In regulated industries, incomplete scan records compromise compliance

What used to be manageable with low SKU counts and slower fulfillment has now become a liability.

Why Manual Scanning Falls Short in Warehouses

The penalty of scanning manually one-buy-one is most noticeable in scenarios such as:

- Pallets arriving at receiving – Stacked items with multiple SKUs. Workers may need to move items or cut plastic wrap. Duplicate scans and missed barcodes slow down throughput.

- Bulk storage bins or totes during picking – Densely packed containers with items stacked or jumbled together. Workers may need to unpack items to access individual barcodes. Manual scanning means slower pick confirmation and higher chance of errors.

- Cycle counting across densely packed shelves – Cycle counts should be minimally disruptive but manually scanning densely packed shelves slows the process and undermines accuracy. Items are more easily skipped or double counted.

- Inbound QA or blind receipts – Items arriving without a packing list or needing inspection before receiving need to be scanned and verified manually. There’s no quick way to verify completeness without full unpacking. Receiving errors (wrong quantity or wrong item) need visual confirmation.

In these scenarios, manually handling and scanning items one at a time is not only slow—it also increases the chance of human error, especially when barcodes are small, misaligned, or partially obscured.

A New Approach: Batch Scanning

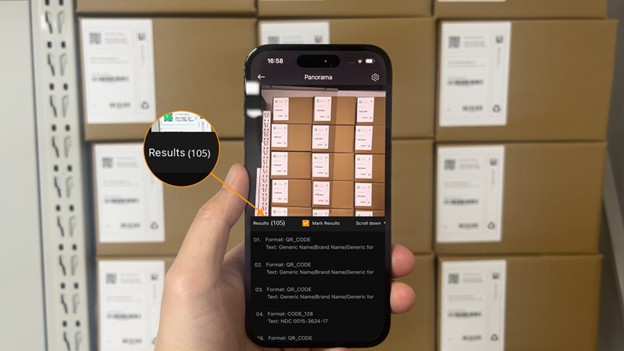

To address these challenges, many warehouses are now considering batch barcode scanning: scanning all barcodes in view at once. Batch barcode scanning uses advanced capture techniques that detect, decode, and record multiple barcodes in a single image-based scan.

This emerging approach allows workers to:

- Scan 100+ barcodes at once using a mobile device

- Instantly count quantities of each SKU

- Quickly find specific items in the batch

- Verify items and create a visual record that shows exactly what was scanned

- Maintain traceability and compliance without extra paperwork or manual logging

Warehouse Use Cases for Batch Scanning

Receiving

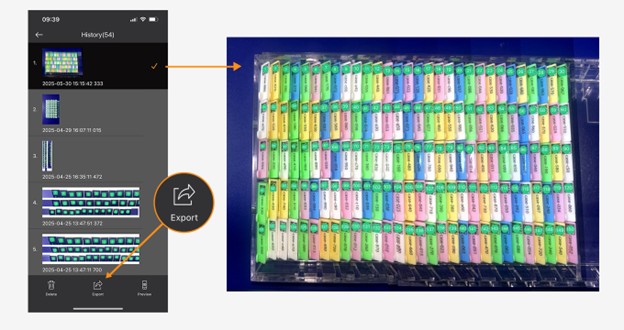

Scan complete pallets on arrival. Check contents in a single scan – even with mixed SKUs. Verify inventory with an image of the complete scanned area and save as .CSV file for archive.

Picking

Find the correct item quickly in a stack, shelf or drawer. Confirm that the correct items were picked before shipment, without manually scanning each label.

Auditing

Complete rapid cycle counts or spot checks using a bulk scan of the complete set instead of paper-based checklists.

Compliance & QA

Capture visual evidence of inventory checks, lot numbers and expiry dates for regulated goods such as food, pharmaceuticals or electronics.

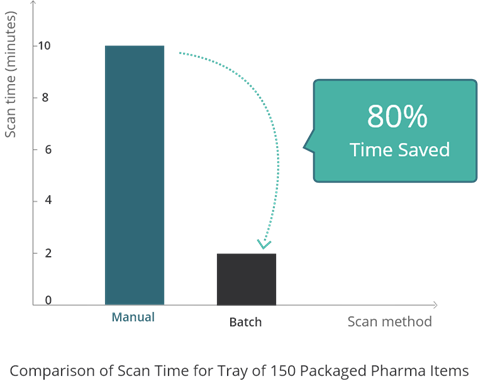

80% Time Savings

The most immediate and measurable benefit of batch scanning is the dramatic reduction in time spent on routine inventory tasks. Manually scanning 150 items can easily take more than 10 minutes with a handheld scanner, especially when barcodes are small and densely packed. With batch scanning, the same task takes only 2 minutes – 80% time savings. This compounds across multiple transactions each day and across warehouse operations, freeing up staff and increasing overall warehouse throughput.

More than Speed - Accuracy and Traceability

The advantage of batch scanning is not just speed – it’s also about accuracy and traceability. When bulk scanning is integrated into warehouse management systems, operations gain:

- Fewer missed scans and inventory mismatches

- Visual proof for audits or compliance reviews

- Faster identification of expired items or lots

- Reduced worker fatigue and scanning errors

As warehouses grow ever more complex, and fulfilment expectations soar, these benefits compound, making a strong case for re-evaluating scanning strategies.

Time to Rethink Scanning

Barcode scanning remains a bottleneck in otherwise efficient warehouse operations. The technology to transform receiving, inventory checks and order verification is now here. Batch scanning offers a practical, scalable way to remove bottlenecks while improving accuracy and reinforcing compliance. It’s time to scan smarter.

Dynamsoft Batch Barcode Scanner

Our Batch Barcode Scanner is designed to scan 100+ barcodes. It is effectively unlimited since we read multiple frames and panoramic stitching techniques. Our solution is currently available for iOS, Windows, Linux and JavaScript (beta).

Watch the video to see batch scanning in action.

Ready to start scanning smarter?

Schedule a call to discuss your specific use case.

Blog

Blog