Batch Scanning Tiny DataMatrix Codes for Electronics Manufacturing Automation

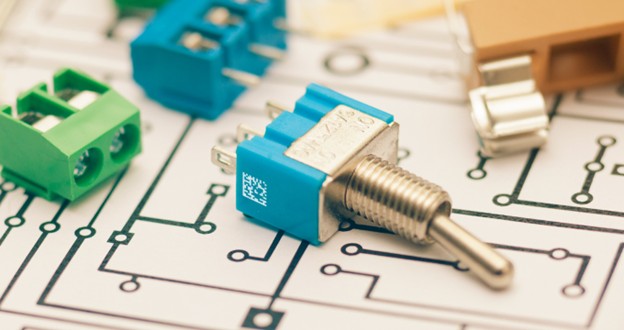

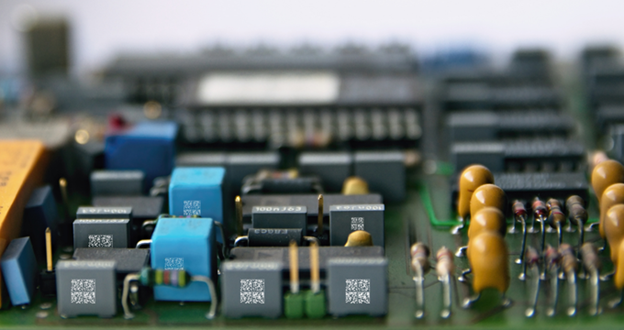

Modern electronics manufacturing operates at high speed, processing billions of small components such as printed circuit boards (PCBs) and integrated circuits daily. Accurate tracking of each component is essential. Among the most sophisticated identifiers used in this field are small DataMatrix codes, tiny 2D barcodes etched or printed directly onto miniature components, a process known as Direct Part Marking (DPM). However, the traditional method of scanning these codes one by one is a major bottleneck; it’s slow, prone to human error, and a drain on resources.

Manufacturers face a clear challenge: how can you scan an entire tray of hundreds of tiny components in a single shot with 100% accuracy? The answer lies in automated batch scanning.

The Microscopic Challenge: Why Traditional Scanning Can’t Keep Up

Scanning an entire tray of components at once isn’t as simple as taking a picture. The unique environment of electronics manufacturing introduces multiple factors that exceed the capabilities of standard scanning technologies.

Size and Density: Tiny Barcodes

The primary challenge is scale. DataMatrix codes on electronic components are incredibly small, often measuring just a few square millimeters. Their data is encoded in a grid of “modules” (the black and white squares), with high-density codes packing a significant amount of data into a tiny footprint (e.g., a 10 x 10 module grid in a 2 x 2 mm space). For any scanner to work, its optical resolution must be high enough to clearly distinguish these individual modules. When a single camera needs to resolve hundreds of these tiny codes spread across a large tray, the required image resolution skyrockets.

The Manufacturing Environment is Unforgiving

Beyond size, the physical characteristics of the components and their markings create further complications:

- Low Contrast: Codes are often created using dot peening or laser etching (Direct Part Marking), resulting in low contrast between the modules and the substrate material. This makes them difficult for standard cameras to differentiate.

- Surface Irregularities: Components are not perfectly flat. Codes can be on curved surfaces, creating perspective distortion. Glare and reflections from metallic or glossy surfaces can obscure parts of the code, rendering it unreadable.

- Inconsistent Placement: While automation aims for consistency, components within a tray may have slight variations in position and orientation, which a scanning system must be able to accommodate.

The High Cost of “Good Enough”

Manual scanning, or using systems that aren’t 100% accurate, introduces unacceptable risks. A single missed scan can have cascading consequences:

- Line Stoppages: If a component isn’t registered, the entire assembly line may halt until the issue is resolved.

- Compromised Traceability: A gap in the data chain results in a loss of traceability, creating a compliance and quality control nightmare, especially in automotive or medical electronics.

- Costly Rework: A batch with unscanned components may need to be flagged for manual inspection and rework, negating any automation benefits.

What takes a human operator a few seconds per component can balloon into 15-20 minutes of tedious, error-prone work to clear a single tray. This is simply not sustainable in a high-volume production setting.

The Solution: High-Resolution Vision and Intelligent Software

The answer is a two-part technological solution that replaces the single-file manual process with a massively parallel automated one. This “one-shot” tray scanning system works in a coordinated sequence.

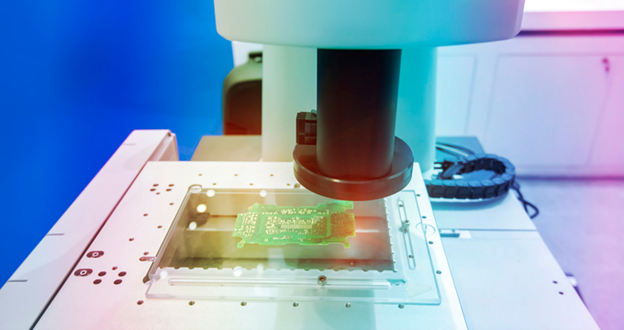

Step 1: The All-Seeing Eye - Capturing the Perfect Image

It all starts with the image. To capture every minute detail across a wide area, the system uses a high-resolution industrial area scan camera (often 20 megapixels or more) mounted above the component tray. But the camera is only part of the equation.

- Advanced Optics: A telecentric lens is often used to ensure that components are seen without perspective distortion, regardless of their height or position in the tray. This makes every barcode appear uniform in size and shape to the camera.

- Controlled Lighting: Specialized lighting, such as a dome light, creates diffuse, uniform illumination across the entire tray. This minimizes shadows and eliminates specular reflections (glare) from shiny surfaces, ensuring the barcode markings are captured with maximum contrast.

Step 2: The Brains of the Operation - Advanced Decoding Algorithms

Once a clear, high-resolution image is captured, powerful software takes over. This is where the real action happens. The decoding process involves several sophisticated steps:

- Image Pre-processing: The software first applies algorithms like binarization to convert the grayscale image into a pure black-and-white format, enhancing the contrast of the barcodes.

- Barcode Localization: The software then scans the entire image to rapidly identify regions of interest that look like DataMatrix codes. It can locate hundreds of codes in milliseconds, irrespective of their orientation or position.

- Intelligent Decoding: For each located code, the decoding engine gets to work. It’s built to be resilient, using error correction algorithms like the Reed-Solomon method to successfully read codes that are partially obscured, damaged, or distorted.

- Data Aggregation and Verification: Finally, the software compiles the data from all successfully decoded barcodes into a structured list and can even verify it against a master list to confirm that no components are missing. This complete dataset is then passed to the Manufacturing Execution System (MES).

This entire process, from image capture to data delivery, is completed in a matter of seconds.

Why Batch Scanning is a Game-Changer

Batch scanning offers a transformative leap over manual workflows. Instead of scanning components one at a time, a system captures a panoramic or high-resolution image of the entire tray, processing dozens, or even hundreds, of DataMatrix codes simultaneously.

Adopting a batch scanning system isn’t just a technical upgrade; it’s a strategic business decision with a clear return on investment. The key benefits that drive this ROI include:

- Massive Throughput Increase: Scan hundreds of components in the time it used to take to scan one. This dramatically accelerates production cycles.

- Unbeatable Accuracy: Sophisticated algorithms ensure a decoding accuracy rate of virtually 100%, eliminating human error and ensuring data integrity for traceability.

- Enhanced Traceability: With complete and accurate data capture at every stage, manufacturers gain full visibility into their production process, simplifying quality control and recalls if necessary.

- Reduced Labor Costs: Automation frees up valuable human operators from repetitive scanning tasks, allowing them to focus on more complex, value-added activities.

Powering Industrial-Grade Automation with Dynamsoft Batch Barcode Reader

The success of any automated batch scanning system hinges on the power and reliability of its “brains”, which is the decoding software. This is precisely where the Dynamsoft Batch Barcode Scanner SDK provides a decisive advantage.

Engineered for the most demanding industrial environments, our SDK is not a generic, off-the-shelf solution. It is a powerful toolkit specifically optimized for the challenges of electronics manufacturing:

- Unmatched Decoding Performance on Small DPM Codes: Our algorithms are fine-tuned to excel at reading the most challenging DataMatrix barcodes, including the tiny, low-contrast Direct Part Marking (DPM) codes, even those affected by glare or printed on uneven surfaces.

- Blazing Speed for High-Resolution Images: Dynamsoft Batch Barcode Scanner is built for performance, leveraging multi-threading and advanced algorithmic efficiencies to process massive, high-resolution images in seconds, ensuring your production line never has to wait.

- Enterprise-Grade Resilience: We’ve designed our SDK to handle real-world imperfections. It intelligently corrects for perspective distortion, rotation, and minor damage, delivering an industry-leading read rate where other solutions fail.

- Flexible and Seamless Integration: Available for all the leading platforms, our SDK is designed to be easily integrated into your existing manufacturing execution systems and software infrastructure, significantly reducing development time and cost.

Don’t let manual scanning dictate the pace of your production. Power your automation with an SDK designed to see, read, and process everything in a single shot.

Ready to transform your component traceability?

Contact our team to discuss your project or download a 30-day free trial to experience the power of the Dynamsoft Batch Barcode Scanner firsthand.

Blog

Blog