Smarter Kitting and Safer Medical Devices Transformed with Intelligent Barcode Scanning

In the intricate world of medical device manufacturing; compliance, accuracy, and patient safety remain at the core. A missed scan, a miskitted tray, or an incomplete audit record can cause disruption in the entire production line. Even small errors cause delays, costly reworks, or regulatory findings.

To minimize these risks, medical device manufactures are increasingly moving towards Intelligent barcode scanning. The right solution ensures accuracy, traceability, and accountability. This blog explores key kitting challenges and how smart scanning solves them.

Why Kitting Becomes a High-Stakes Bottleneck with Traditional Barcode Scanning

Kitting is one of the most challenging steps in mobile device manufacturing as it requires high accuracy in choosing, arranging, and documenting components. A single tray can contain dozens of small parts, each with strict placement and sequencing rules. Operators must scan and validate every piece under time pressure, while QA teams require complete traceability for compliance. Without a system that enforces accuracy, kitting becomes a high-stakes bottleneck in production.

The difficulty is compounded by the limitations of traditional barcode scanners, which were never designed for such high-stakes environments:

- Line Operators: Managing dozens of scans per tray is time-consuming, repetitive, and mentally exhausting. Conventional barcode scanners are limited to confirming an item’s presence but lack modern functionalities, such as validating the correct sequence or tray position. This leaves room for mistakes that are mentally exhausting to catch manually.

- QA/RA Teams: Kitting generates a large amount of data and managing it manually can create gaps in records. Missed or incomplete scans result in unreliable audit trails, making the business vulnerable to compliance risks.

- Industrial Engineers: The lack of automation leads to inefficient workflows, frequent rework, and reduced throughput, making it difficult to keep pace with demand.

- Business Risk: Altogether, these challenges result in slowdowns, scrap, and non-compliances, affecting both financial performance and reputation.

Smarter Kitting Traceability with Dynamsoft Barcode Reader

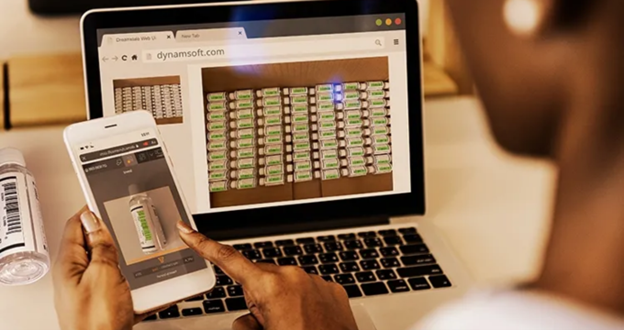

Dynamsoft Barcode Reader (DBR) is an advanced barcode reader designed to meet the high demands of manufacturing. It automates and streamlines the kitting process, ensuring that all items are scanned correctly and quickly before trays are moved forward, leaving no room for human error. Operators receive instant feedback on duplicated or missed scans, so issues don’t escalate.

DBR’s integration with ERP and MES systems provides detailed, actionable visibility throughout the manufacturing process. This capability transforms barcode scanning beyond simple data capture, giving organizations comprehensive traceability, rapid exception handling, and adaptable workflows tailored to the needs of regulated production lines.

- Must-Scan Enforcement: DBR ensures that trays don’t progress until every barcode has been scanned, helping to eliminate oversights.

- Sequence & Position Awareness: It guarantees correct placement by validating each scan against the expected tray or order layout.

- Real-Time Operator Feedback: Operators receive instant alerts for duplicate or missed scans, enabling them to correct errors before they escalate.

- Flexible Integration: Dynamsoft Barcode Reader SDK is highly customizable and works seamlessly across web, desktop/server, and mobile platforms, allowing for smooth integration across ERP/MES systems.

- Per-Unit Genealogy Export: Each barcode scan is logged, time-stamped, and linked to a device’s digital record for instant audit readiness.

Tangible Benefits Across the Organization

Numbers speak volumes when it comes to the benefits that DBR provides in the medical device manufacturing industry. It ensures operations remain both efficient and compliant.

Quantitative Results

Here is a snapshot of measurable improvements that manufacturers achieve by choosing Dynamsoft Barcode Reader.

- Rework Rate ↓ 50%+: It enforces scanning every item, which significantly reduces the likelihood of costly errors and waste.

- Scan Omissions ↓ 80%: By sharing real-time alerts, DBR ensures all barcodes are captured before trays move forward.

- Audit Prep Time ↓ 40%: QA teams can easily export genealogy records that help save hours of manual effort.

Impact by Role

Below is an overview of how different teams are impacted by leveraging DBR as a barcode scanner for medical manufacturing.

- Line Operators: Guided workflows reduce stress and catch errors instantly, making daily tasks easier.

- QA/RA Teams: Complete genealogy data is instantly accessible, reducing audit preparation from hours to minutes.

- Industrial Engineers: With fewer stoppages and errors, production runs smoothly, and throughput improves.

Compliance Edge

Dynamsoft Barcode Reader ensures full barcode traceability, supports regulatory readiness, and enables fast audit and recall response. Here is how:

- FDA 21 CFR Part 11 & ISO 13485: As DBR enforces mandatory barcode scanning, logs every action with a time stamp, and securely links each record to the device’s digital history, it helps support data integrity, audit trails, and traceability requirements outlined in 21 CFR Part 11 and ISO 13485.

- Audit Confidence: Each scan is saved as part of the device genealogy, allowing auditors to instantly access a complete history of what was scanned, when, and by whom, thereby eliminating gaps in compliance documentation.

- Rapid Response: In the event of a recall or deviation, DBR’s per-unit genealogy allows manufacturing teams to quickly trace affected devices, isolate them, and prevent unsafe products from reaching patients.

Getting Started with Dynamsoft

Medical device manufacturing can’t risk errors. Hence, using enterprise-grade barcode scanning becomes essential. Choosing the Dynamsoft Barcode Reader SDK streamlines kitting workflows for smoother, safer production.

Contact our technical support team to discuss how Dynamsoft Barcode Reader can address your specific manufacturing challenges.

Blog

Blog