Free

Trial

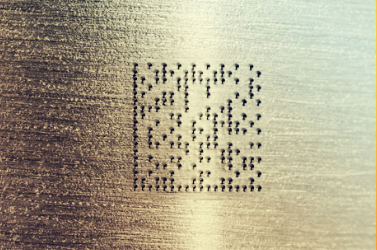

Dynamsoft Barcode Reader SDK supports decoding Direct Part Marking (DPM) Data Matrix and QR codes. It is ideal for anyone who manages or tracks components, devices or equipment with permanently etched DPM barcodes. This is whether it is etched into silicon, metal, plastic, or glass.

Common Applications of Direct Part Marking

Electronics Manufacturing

Keep track of assembly throughout the factory and across supply chains.

Automotive

Reliably track automotive subsystem components to process orders or warranties.

Aerospace

Monitor the status of mission-critical devices with efficient barcode data.

Medical Devices

Track the status, location and more of devices being used for patient treatments.

Features

Supports all platforms: Android, iOS, JavaScript, Linux, Windows

Supports decoding DPM codes from static images, PDFs, and video streams

Supports decoding Data Matrix and QR codes

Dynamsoft Barcode Reader SDK is Optimized for Challenging DPM Codes

Dynamsoft uses proprietary algorithmic capabilities to quickly resolve DPM barcode scan challenges. This results in successful DPM scans on par with traditional barcode decoding, despite their being more scan challenges.

Color and Contrast

Etched barcodes have the same color as the surface they’re on. The front and the background usually only differ in color because of contrast from shadowing. This makes decoding difficult. Also, a lack of uniformity with printing means dots can be a different depth and so shadows can vary.

Dots

DPM uses dots instead of lines like in common barcodes. If those dots are too close together, or too far apart, they can cause decoding errors. Also, the shape of dots can be inconsistent from imperfect etching. Some can appear as circles; others can be square-like or star-shaped.

Surface Imperfections

The quality of DPM etchings can be affected by the make-up of textures they are on, which can be reflective, uneven or curved surfaces. These surfaces themselves can have their own imperfections. This can include damage, micro divots or abrasions. These items can all interfere with a scanner’s ability to read.

Lighting

DPM symbols are often printed on curved metal surfaces and when viewed under ambient light do not always offer the most ideal contrast. Often, DPM barcodes are placed in areas where light is difficult to reach them. There are a variety of other possible lighting challenges with DPM barcodes.