Why Digital Product Passports Need DPM Barcodes — And How to Enable Accurate Scanning

Across both the EU and the US, a major shift is underway: products are beginning to carry persistent, scannable digital identities that track their history, materials, and lifecycle from manufacturing to end-of-life. The concept isn’t fully standardised worldwide yet, but momentum is accelerating - and hardware manufacturers need to prepare.

This is where Digital Product Passports (DPPs) come in, and why Direct Part Mark (DPM) barcodes are becoming essential across electronics, industrial hardware, and medical devices.

Below, we break down what digital passports are, where they’re required, and how Dynamsoft fits into the future of high-precision identity capture.

What Are Digital Product Passports?

Digital Product Passports (DPPs) are digital records of a product’s identity, materials, and lifecycle data, linked to the physical product using a scannable ID — usually a barcode, QR code, or RFID tag.

A DPP typically includes:

- Product identifiers and serial numbers

- Material composition

- Repair history and maintenance logs

- Environmental and energy data

- Compliance and certifications

- Recyclability and end-of-life instructions

- Ownership or service records

A passport follows the product for its entire lifespan, meaning the identifier must be durable and machine-readable for years.

Where Are Digital Passports Required? — EU vs US

Europe: Mandatory and Expanding

Europe is the global leader. Under the EU Circular Economy Action Plan, DPPs will be required for:

Already mandated / first wave:

- Batteries

- Textiles

- Consumer electronics

- Industrial electronics

- Construction materials

Expected next:

- Medical devices (to complement UDI)

- Automotive components

- White goods and household appliances

If hardware is sold in the EU market, manufacturers will not be able to avoid DPP compliance long-term.

United States: Not “DPP” by name, but the same trend

The US doesn’t use the term “Digital Product Passport,” but similar requirements are emerging through:

- Extended producer responsibility (EPR) laws

- Right-to-repair legislation

- FDA UDI for medical devices

- GS1 digital link adoption

- Sustainability and provenance transparency requirements from major retailers

In practice, US electronics and medical device manufacturers selling globally will need to meet EU DPP standards anyway.

Result:

Digital identity is becoming a global expectation, even without a unified regulatory framework in the US.

Which Hardware Will Require Digital Passports?

DPP rules vary, but the underlying pattern is clear:

if a device has long life, service cycles, repairability, or sustainability value, a digital passport will be required.

High likelihood of DPP requirement

- Industrial electronics

- IoT hardware

- Medical devices

- Batteries and power modules

- Automotive and EV components

- Industrial machinery

- Renewable energy systems

- Telecom and networking equipment

- Consumer electronics (medium/high value)

Lower likelihood (for now)

- Disposable consumer gadgets

- Low-value electronics accessories

- Non-serviceable components

But even here, component suppliers may be required to provide traceability upstream.

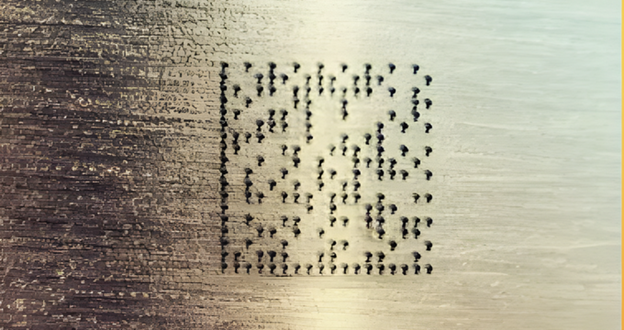

Why DPM Barcodes Will Dominate DPP Identification

Digital passports require identifiers that survive heat, abrasion, solvents, vibration, sterilization, and multi-year use.

That’s why Direct Part Marking (DPM) is becoming the default for traceable hardware.

DPM advantages

- Permanent marking (laser, dot-peen, electrochemical, molded-in)

- Resistant to wear and environmental exposure

- Hard to remove, helping prevent counterfeiting

- Supports high-density DataMatrix codes for long serials

- Works on metals, plastics, ceramics, composites

If the identifier needs to last: DPM beats printed labels every time.

Expected widespread DPM use:

- Electronics PCBs

- Battery cells and modules

- Surgical instruments and reusable medical hardware

- Motors, pumps, actuators

- Aerospace and automotive parts

- Telecom equipment

- Industrial machinery components

The Challenge: DPM Codes Are Hard to Read

DPM marks often have:

- Low contrast

- Specular glare from metal surfaces

- Tiny code sizes

- Distortion from curved surfaces

- Damage or wear

- Non-uniform marking depth

Most traditional barcode SDKs or built-in scanners struggle with DPM — especially in mobile or embedded environments.

This is where Dynamsoft stands apart.

Why Dynamsoft Is the Barcode Reader of Choice for DPM and Digital Passport Readiness

DPP compliance depends on a reliable 1:1 relationship between a physical product and its digital record. If a DPM barcode fails to scan, the digital passport breaks — inspection stops, compliance flags trigger, and traceability fails. Dynamsoft’s technology is engineered specifically to prevent that.

1. AI-driven decoding built for difficult DPM conditions

Dynamsoft’s DPM recognition leverages advanced AI models and proprietary vision algorithms to extract codes from surfaces and marking conditions where conventional scanning fails. This includes:

- Ultra-low-contrast laser marks

- Dot-peen codes on raw or anodized metal

- Glossy or reflective surfaces that flare under lighting

- Micro-DPM codes with tiny modules

- Codes on curved housings or cylindrical components

- Partially occluded or damaged codes

Our AI driven DPM barcode scanning improves accuracy and reliability significantly. This matters for DPP workflows because one unreadable stamp can break the entire compliance chain.

2. Hardware-agnostic scanning for real-world workflows

Dynamsoft runs consistently across every environment where hardware identity must be captured. Dynamsoft’s solutions run on:

- Mobile (iOS, Android)

- Web browsers

- Embedded devices

- Windows, Linux, macOS

- Industrial scanners and custom devices

Organizations don’t need separate scanning logic for each device. Whether a technician is holding a ruggedized tablet at a tarmac, a quality operator is using a workstation on a manufacturing line, or a developer is integrating scanning into a browser-based maintenance tool, Dynamsoft maintains uniform decoding behavior and predictable performance.

3. Fast, deterministic decoding for edge devices

In automated workflows such as DPP or UDI (Unique Device Identification), scanning performance directly impacts throughput. Dynamsoft ensures sub-100ms instant decoding and working offline. This is particularly valuable in use cases such as robotic pick-and-place operations, automated QA systems, industrial handhelds and self-service repair kiosks. By providing consistent minimal latency and eliminating dependency on cloud inference, the scanning process remains stable, secure, and fast under real-world load.

4. Trusted in regulated, high-consequence industries

Dynamsoft’s solutions are already deployed in environments where scanning accuracy directly affects compliance, safety, and operational continuity — including UDI medical regulations, aerospace and automotive serialization, defense-sector supply chains, industrial asset tracking, and electronics manufacturing. Customers rely on DPM recognition in places where mistakes can’t be tolerated: inside hospitals, on assembly lines, in aircraft hangars, and throughout globally regulated manufacturing networks.

Dynamsoft - Precision DPM decoding for Digital Product Passports

Digital Product Passports are becoming the backbone of global hardware traceability - whether through EU regulation or US-driven sustainability and data transparency requirements. As electronics, medical devices, and industrial hardware adopt permanent identifiers, DPM barcodes will become the standard for durable, compliance-ready marking. And to make this ecosystem work, organizations need a barcode engine that can reliably decode the most difficult marks in real-world conditions.

Dynamsoft delivers exactly that: precision DPM decoding for the next generation of global product identity.

Next steps?

Talk to a specialist to identify how Dynamsoft can solve your challenges with highly accurate DPM scanning.

Test our barcode scanner with the online demo.

Key Takeaways

-

Regulatory Momentum: Digital Product Passports (DPPs) are becoming mandatory in the EU and are increasingly relevant in the US, requiring persistent product identification throughout the lifecycle.

-

Why DPM Matters: Direct Part Marking (DPM) provides permanent identifiers that resist heat, abrasion, chemicals, and time, where labels and stickers are ineffective.

-

Decoding Complexity: DPM barcodes frequently present low contrast, reflective surfaces, and background noise, which makes AI-powered decoding essential.

-

Industrial-Grade Scanning: Dynamsoft SDKs are designed to address challenging DPM scenarios across mobile, desktop, and embedded hardware.

-

Benchmark Insight: Compare real-world DPM decoding performance in our Data Matrix reading benchmark and comparison.

Blog

Blog