How is Barcode Technology used in Stock Control?

Effective stock control is crucial for businesses. It helps avoid overstocks, shortages, or other costly problems or issues within the warehouse while simplifying processes and improving forecasting. Barcode technology plays a vital role in ensuring robust stock control.

-

i. What are the Different Types of Inventory Stocks?

-

How Barcode Technology is Used in Stock Control

i. Benefits of Using Barcode Technology in Stock Control

ii. 3 Best Practices for Using Barcodes in Inventory Tracking Systems

iii. Barcode Inventory System: Common Challenges Faced by Inventory Professionals

iv. How does Dynamsoft Barcode Reader SDK address these Issues?

Understanding Stock Control

Stock control, or inventory control, involves maintaining the apposite quantity of stock to allow businesses to meet customers’ demands evading delays while retaining the minimum costs of the holding stock.

Any business that deals with physical products require stock or inventory to sell. Stock control helps ensure that the company always has enough inventory for the customers as it balances the cost invested in acquiring and storing the stock. The process seems easier when said than done. Multiple factors outside the control of the business can be involved that further make stock control even more complex.

What are the Different Types of Inventory Stocks?

Essentially, there are four types of inventory stocks. These are listed below.

-

Raw Material: Any materials that transform your stock or inventory into a finished good or product are termed raw material.

-

Work-in-Process (WIP): As clear from its name, any inventory or stock being worked on is referred to as work-in-process.

-

Finished Goods: The inventory item ready to sell is a finished good.

-

Maintenance, Repair, and Overhaul (MRO) Goods: MRO inventory involves the items that help assemble or build a finished good rather than being sold standalone.

How does the Inventory Stock Control System work?

Inventory control becomes easier when you know what type of stock you have. When it comes to an inventory or stock control system, it is a technology solution that automates multiple manual processes to successfully track and manage a company’s goods through the supply chain. Barcode recognition is a critical technology that enhances inventory tracking and management, resulting in a robust inventory control system. Choosing a good barcode-based inventory control solution will further strengthen the process.

2 Types of Inventory Stock Control Systems

Any finished goods or raw materials that organizations use for production or selling to customers on the markets are referred to as inventory or stock. An inventory stock control system can be divided into two types, perpetual inventory system, and periodic inventory system.

-

Perpetual Inventory Control System: As the name suggests, it keeps track of stock balances perpetually or continuously while automatically updating whenever a product is sold or received.

-

Periodic Inventory Control System: In contrast to the perpetual inventory accounting system, the periodic inventory system uses occasional physical counts to track the cost of the goods sold and measure the stock level.

How Barcode Technology is Used in Stock Control

For businesses that rely on physical products, stock control can be the deciding factor between profit and loss. When done correctly, it can help increase profitability on each sale while keeping costs down. With barcode technology, businesses can automate tedious manual processes involved in stock control to improve efficiency and accuracy.

A barcode-based inventory management system assigns a barcode to every inventory item. The barcode label on each item is scanned using a barcode scanner as it traverses through the warehouse process.

Throughout the stock control process, barcodes can be used in multiple ways, such as:

- To pick orders

- Conduct inventory counts

- To receive orders

- Warehouse transfers

Benefits of Using Barcode Technology in Stock Control

One of the main reasons barcodes have become ubiquitous in different industries is that they help build a standard to identify the same product or item across the supply chain. For example, when a product is developed, the manufacturer can assign it a UPC or Unique Product Code barcode label for fast product identification. The manufacturer, consumers, distributors, retailers, etc., can access accurate information using the same UPC.

Automation is the key factor that reduces dependency on manual tasks and eliminates errors in recording data in real time as the item travels throughout the supply chain.

Below are the essential benefits of using barcode technology in stock control.

-

Increased Accuracy: A barcode inventory system ensures the accuracy of the stock count as it minimizes dependency on manual data entry of product information at the time of receiving while reducing the chances of errors.

-

Boost in Efficiency: Manual data entry is time-taking and error-prone. Barcode inventory control reduces the time spent manually entering product information and rectifying errors. As a result, enhanced efficiency.

-

Real-time Data: Whenever an employee scans a barcode on a product, the stock and sales numbers are quickly updated in the business management system or the ERP (Enterprise Resource Planning) solution of the company.

-

Reduced Cost: Barcode technology is cost-effective. The upfront investment in implementing a barcode stock control system is low compared to other modern technological solutions. With mobile devices becoming more prevalent, businesses can refrain from investing in dedicated devices and save significantly.

3 Best Practices for Using Barcodes in Inventory Tracking Systems

Inventory tracking is critical for many businesses. While it’s certainly more critical to some industries, such as retail, other industries can also benefit. Here are some basic considerations if you’re thinking of implementing an inventory tracking system into your business.

- Inventory Tracking System- What do you want from it?: The benefits of having an inventory tracking system, particularly one with barcodes at the core, become apparent in the retail industry. But what if you’re a CIO or IT director at a non-retail organization? Perhaps there are asset tracking advantages for you too.

First, sit down with relevant stakeholders to figure out what features would be important. Don’t work backward; find a system, then figure out how to apply its features. Instead, figure out your problems and how you want them solved. Then, ensure the vendors your vetting can specifically address them. You’ll also want to determine if you need integration into existing or new systems.

- Try before you buy: Test your software and barcode labels before deploying your entire barcoding system. Don’t make the mistake of just starting to use them. You might discover the labels you’ve chosen aren’t resilient enough or the barcode hardware you selected isn’t efficient in scanning right the first time. On the software side, you might discover you want more data from your barcode or to use different barcode types for differing products or assets.

Sophisticated barcode reading software will offer dozens of ways to improve barcode recognition accuracy.

- Build a Back-Up for your Inventory Tracking System: It should go without saying that a redundant backup plan should be in place. This isn’t just for your data too. You might consider having a backup inventory tracking system, mainly if its uptime is mission-critical. Today’s cloud computing solutions offer a variety of options for backups, whether you want a total cloud approach or a hybrid local and cloud approach.

Barcode Inventory System: Common Challenges Faced by Inventory Professionals

Although barcode technology benefits inventory professionals in multiple ways, a weak barcode inventory system can pose several challenges. The common ones are listed below.

-

Slow Processing: A slow barcode scanner is as good as manual data entry. It leads to poor efficiency and frustration.

-

Lack of Support for Multiple Platforms: A barcode scanner app may not work with drones, automated guided vehicles (AGV), or mobile robots that warehouses often use for effective inventory tracking. Most barcode scanning solution providers do not offer support for multiple platforms and devices.

-

Difficult to Integrate: Integrating barcode scanning capability into different devices and platforms takes time and effort. Ordinary barcode scanning solutions can take months of development to function.

-

Not Able to Scan Tough Barcodes: When dealing with thousands of items, chances are high that barcode labels may get damaged for multiple reasons. Weak barcode readers cannot scan torn, incomplete, angled, wrinkled, tiny, or marked-up barcodes posing another challenge for inventory professionals.

-

Difficulty reading barcodes in Challenging Environments: Another problem with weak barcode scanners is their failure to perform in challenging environments such as low light, shadow, and glare.

-

No Support for Batch Scanning: Inventory professionals scan thousands of barcode labels daily. Scanning a single barcode at a time impacts productivity. Ordinary barcode scanners do not support batch scanning.

-

Poor Performance Due to Suboptimal Cameras: Sub-optimal cameras can significantly hinder barcode scanning for stock control in inventories, decreasing the efficiency and accuracy of the entire process. The quality of cameras directly influences the ability to capture clear and precise images of barcodes, and poor performance in this regard leads to errors and delays. Inaccurate scans can result in misidentification of products, causing discrepancies in inventory records and potentially leading to stockouts or overstock situations.

Low-resolution or distorted images from subpar cameras may also struggle to decipher barcodes in challenging lighting conditions or with damaged labels. This increases the likelihood of manual correction interventions, consuming valuable time and resources. Moreover, the overall reliability of the stock control system is compromised, impacting the ability to make informed decisions on restocking, order fulfillment, and comprehensive inventory management.

Investing in high-quality cameras is essential for ensuring the seamless operation of barcode scanning in stock control, mitigating errors, and enhancing the overall efficiency of inventory management processes.

How does Dynamsoft Barcode Reader SDK address these Issues?

Dynamsoft Barcode Reader is an enterprise-grade barcode scanning SDK that allows you to integrate robust barcode reading capability in a web, mobile, or desktop app. Offering hundreds of APIs to cater to your most specific use cases, you can easily build a powerful barcode stock control system for your business.

Here is how it addresses the major challenges inventory professionals face with weak barcode scanning solutions.

-

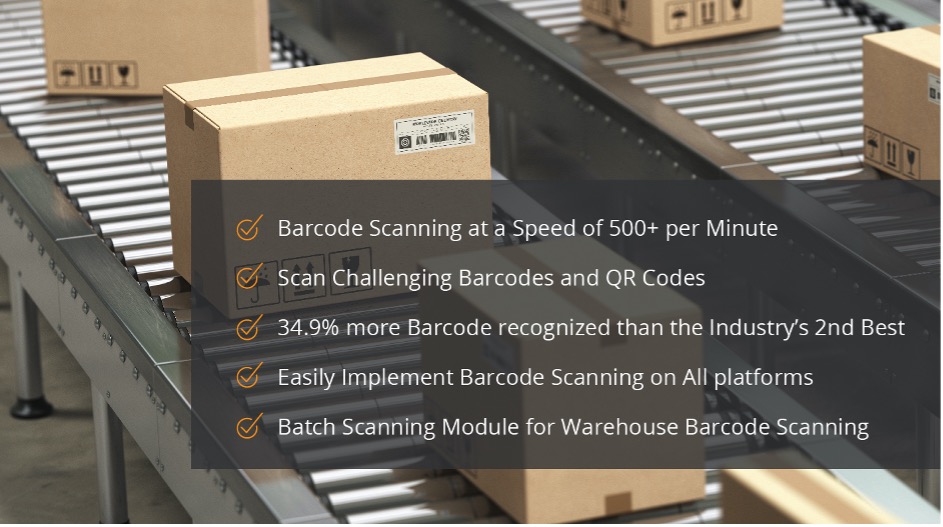

A Barcode Scanner with Brilliant Speed: Dynamsoft Barcode Reader SDK is extremely fast, as it can scan more than 500 barcodes in just 60 seconds! Not to mention, it can read 34.9% more barcodes than the industry’s second-best.

-

Supports a Wide Variety of Platforms: From web apps to mobile, desktop, server, and embedded applications, Dynamsoft Barcode Reader SDK can be implemented on all platforms. Whether you use smartphones or drones for robust inventory tracking, you can do it easily with this barcode scanner solution.

-

Quick Integration Using Just a Few Lines of Code: Build a powerful inventory tracking barcode scanning solution for different devices and platforms using just a few lines of barcode with Dynamsoft Barcode Reader SDK.

-

Ability to Quickly Scan the Toughest of Barcodes: Torn, angled, dense, or tiny- this barcode scanner SDK is built to read all such tough barcodes.

-

Outstanding Performance in Challenging Environments: Glare, shadow, or low light might be a problem for other ordinary barcode scanners but not for Dynamsoft Barcode Scanner SDK.

-

Batch Scanning Module for Warehouse Barcode Scanning: With Dynamsoft Panorama™, an enhanced module of Dynamsoft Barcode Reader, inventory professionals can achieve a true 100% barcode scan success rate when used to its full ability.

Try the Dynamsoft Barcode Reader SDK

Looking for a commercial-grade barcode reader SDK for your inventory management system? Try the Dynamsoft Barcode Reader SDK. It comes with outstanding features and technical assistance at every step of your development for a smooth deployment experience.

Try the online demo for a quick review.

Download the 30-day free trial for a detailed analysis.

If you have any questions, feel free to contact us.

Blog

Blog