DataMatrix - Dynamsoft Barcode Reader SDK

What is a Data Matrix Code?

A high-density 2D barcode symbol, the Data Matrix code has been recognized as a standard of ISO/IEC 16022 since 2000. It can encode numbers, text, files, and data bytes. It uses small square modules, and the perimeter of these modules is purposely different than the interior. Hence, a barcode scanner can identify cell locations for proper decoding.

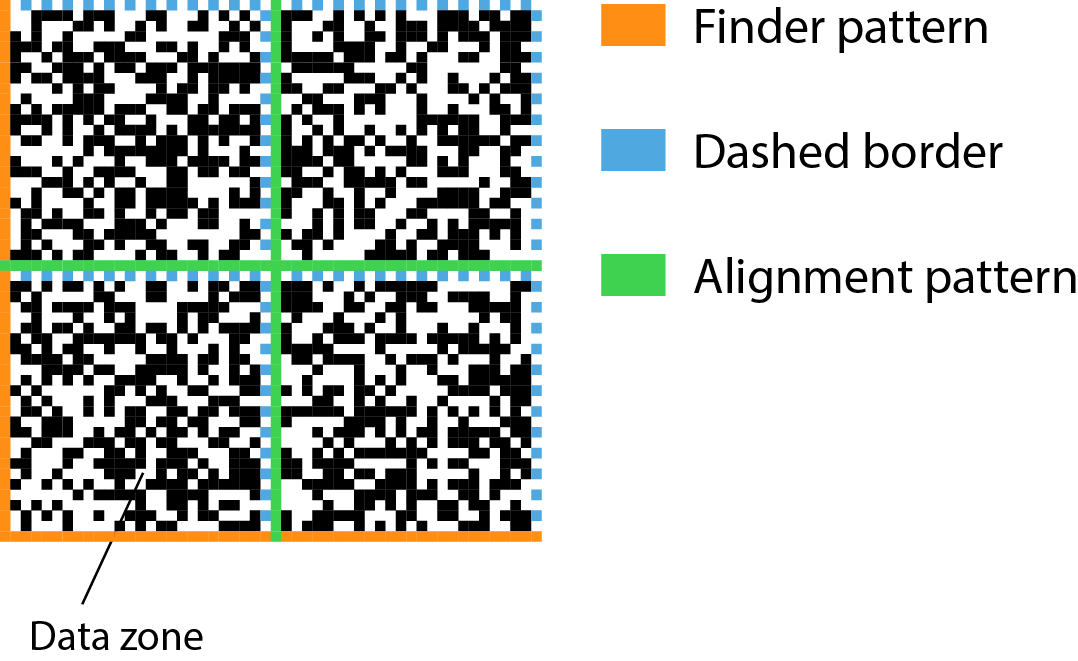

This is what a typical Data Matrix code looks like:

The data area is surrounded by an L-shaped frame, which is often referred to as the "finder pattern". The dotted lines are referred to as the “clock pattern.” These patterns are used to determine the location of parts of the barcode, such as where the edges and data are. A barcode reader will identify the patterns and confirm the bar code location using image processing technologies.

What are Data Matrix barcode specifications & Technical Design?

Error checking and correction

The Data Matrix code is one of the smaller and more reliable barcodes. It supports advanced encoding error checking and correction algorithms. The latest version, ECC200, contains the Reed-Solomon method for error correction and therefore has been internationally standardized. This barcode can often still be scanned even after suffering significant physical damage.

Code size

Data Matrix codes are adaptable in size. The symbol size can be as small as 2.5mm, which is the smallest among all 2D barcodes. Meanwhile, the size and encoded data capacity are independent. This allows the choice of a lot of different matrix sizes.

Square codes

Based on the size of the code, a Data Matrix code can consist of multiple blocks or only one block.

Square Data Matrix codes come in 24 symbol sizes ranging from 10 x 10 modules to 144 x 144 modules. When the code has more than 26 x 26 modules (more than 24 x 24 modules for data), it is divided into blocks. Each separated block does not exceed 24 modules on a side. This structure prevents the distortion of the code. Below is a 4-block code.

| Codes with 26 modules on a side or less have one block. |

| 10 × 10 |

12 × 12 |

14 × 14 |

16 × 16 |

18 × 18 |

20 × 20 |

22 × 22 |

24 × 24 |

26 × 26 |

Codes with more modules will be divided into 4, 16 or 36 blocks:

| Four blocks |

| 32 × 32 |

36 × 36 |

40 × 40 |

44 × 44 |

48 × 48 |

52 × 52 |

| Four blocks |

| 64 × 64 |

72 × 72 |

80 × 80 |

88 × 88 |

96 × 96 |

104 × 104 |

| Thirty-six blocks |

| 120 × 120 |

132 × 132 |

144 × 144 |

Rectangular codes

The rectangular type varies in six different module sizes:

- 8 x 18 modules (1 block)

- 12 x 26 modules (1 block)

- 16 x 36 modules (1 block)

- 8 x 32 modules (2 block)

- 12 x 36 modules (2 block)

- 16 x 48 modules (2 block)

Capacity

Of all the sizes, 144 x 144 has the largest capacity, which can theoretically hold up to 3116 digits, 2335 alphanumeric characters, or 1556 bytes.

Encoding and decoding of a Data Matrix code are considered to be difficult. They are commonly scanned with a camera-based scanner.

Where are Data Matrix Barcodes commonly used?

Label small items

The most popular application for Data Matrix is labelling small items, such as small electronic components and pill bottles.

Industry

Environments with a high risk of contamination

With error checking and correction algorithms, a Data Matrix code is still recognizable with up to even 60% damage. This allows usage under high heat, chemical exposure, environments with a high risk of contamination, and more. Consequently, the Data Matrix code is widely applied to electrical rating plates, surgical instruments, circuit boards, etc.

Industry

- Retail

- Electronics

- Medical

- Mail

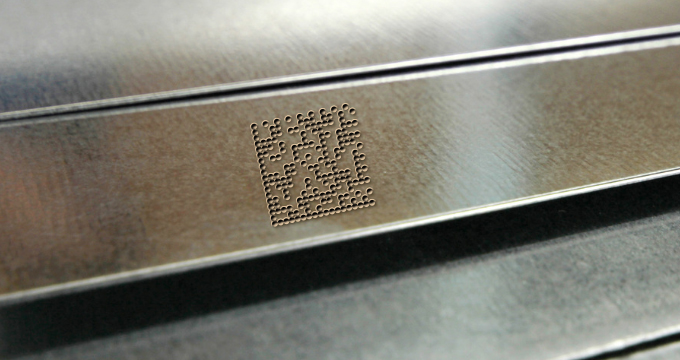

Direct part marking

Direct Part Marking (DPM) is a process that enables people to manage or track components, devices or equipment with a permanently etched barcode. There are many ways to encode information to a machine-readable code. The preferred codes are the Data Matrix and the QR Code.

Source

DPM Data Matrix codes are often used by automotive, aerospace, and electronics manufacturers to facilitate a reliable identification of their parts.

What are Common Challenges While Scanning DataMatrix?

Despite the reliability of standard Data Matrix codes, real-world applications often present significant challenges, which Dynamsoft Barcode Reader is designed to address:

DPM Data Matrix Codes |

Lack of Finder Pattern |

Tiny Codes |

Damaged |

|

|

|

|

Since DPM codes are not printed but rather etched or engraved, the contrast between the code and the background is often low, especially on shiny or reflective surfaces like metal. Variations in lighting, reflections, or surface imperfections such as scratches, dirt, or wear can further complicate detection. |

Finder patterns provide a clear frame of reference that helps barcode scanners quickly locate the code. Without this defining border in Data Matrix codes, scanners have to rely solely on the code's internal structure, and can be more difficult to distinguish from background noise or surrounding objects. |

A Data Matrix code’s size can be as small as 2.5mm. Small codes are more sensitive to print quality, surface conditions, or distortion, and even the slightest imperfection in the printing process can make it hard for scanners to distinguish between the light and dark modules. |

If part of the Data Matrix code is damaged or obscured by labels, packaging, or other materials, it can be difficult for scanners to recover the full data. Although Data Matrix codes have error correction capabilities, extensive damage or occlusion may exceed the threshold of what the scanner can correct. |

How to Scan Data Matrix Codes with Dynamsoft SDK

Dynamsoft Barcode Reader SDK enables you to efficiently embed high-speed and reliable Data Matrix code reading functionality in your web, desktop or mobile application using just a few lines of code.

Download the free trial SDK, explore our helpful resource center including sample codes, tutorials, guides and more to get started.

Decoding All Kinds of Data Matrix Codes – Real World Success Stories

Tiny Data Matrix Scanning - Naturalis ARISE

Naturalis ARISE needed a highly reliable barcode reader that could tackle the challenge of tiny Data Matrix codes on specimen labels accurately. With Dynamsoft Barcode Reader they implemented the solution that not only scans these tiny codes with remarkable accuracy but also supercharges their data capture capabilities.

Read full customer story

Tiny Inverted Data Matrix Scanning - Statens Serum Institut

Statens Serum Institut aimed to revolutionize sample registration for Danish citizens by introducing a seamless web-based mobile solution. The challenge was scanning tiny 4x4 mm inverted Data Matrix codes on sample tubes. They leveraged Dynamsoft Barcode Reader’s robust decoding capabilities of tiny, inverted Data Matrix codes to improve the precision of their biological sample tracking.

Read full customer story

Batch Scanning of Data Matrix Codes – Takeda

Takeda, one of the world’s leading pharma companies, needed to manage large array of sample vials adorned with small Data Matrix codes. By integrating Dynamsoft Barcode Reader into their inventory system, they achieved a staggering 75% reduction in scan time while elevating accuracy.

Read full customer story

Reading Barcodes on Industrial PC Production Link - ADLINK

ADLINK’s IPC production line struggled with unreliable barcode scanning using open-source solutions, creating frustrating bottlenecks in product tracking. With the implementation of Dynamsoft Barcode Reader, they found a robust solution that tackled the difficulties of blurred images from overhead industrial cameras, ensuring smooth product tracking and operational efficiency.

Read full customer story

Laser-Engraved DataMatrix Scanning Under Low-light - Noventi Consulting

Noventi Consulting streamlined tool tracking in the manufacturing industry by integrating Dynamsoft Barcode Reader into a Flutter-based mobile app. The solution enabled fast and accurate scanning of laser-engraved DataMatrix codes on curved, reflective metal surfaces—overcoming challenges like low contrast and poor lighting, improving operational efficiency, reduced human error, and provided instant access to tool maintenance data.

Read full customer story